ABSTRACT:

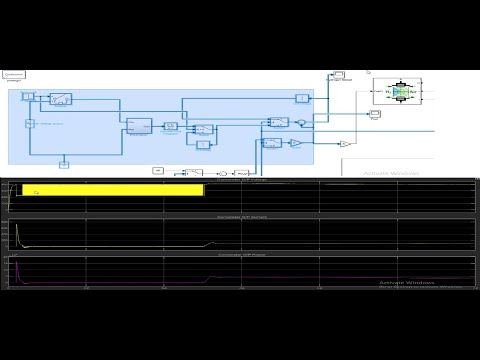

As the global demand for sustainable energy solutions grows, hybrid renewable energy systems have emerged as a promising approach to meet this need. This study explores the design, simulation, and analysis of a hybrid solar photovoltaic (PV) - battery - hydrogen system for sustainable energy production using MATLAB Simulink. The proposed system integrates solar PV as the primary energy source, supported by a battery storage unit and a hydrogen generation and storage subsystem, to ensure a reliable and continuous energy supply. The solar PV system harnesses solar energy during daylight hours, while excess energy is used to charge the battery and produce hydrogen through electrolysis. The stored hydrogen serves as a long-term energy reserve, which can be converted back into electricity via a fuel cell when solar generation is insufficient, such as during nighttime or cloudy periods. The battery system provides short-term energy storage to balance the intermittent nature of solar power and to supply instantaneous power demands. The AI-driven system will strategically allocate surplus electricity generated during peak production phases to power an Proton Exchange Membrane (PEM) electrolyzer. This electrolyzer will efficiently convert excess electricity into hydrogen, storing it for later use in a fuel cell capable of providing electricity during periods of high demand and when solar panels are inactive. The economic viability of the hybrid system was also established, as the cost of electricity generated through the hybrid system was less than half of the grid energy price, meeting the regulatory standards. Optimizing the PEM electrolyzer revealed that a configuration with a few standby parallel PEM electrolyzers was optimal for utilizing excess electricity effectively. Further than that scheduling the parallel system in hourly basis for the days ahead, would help to have more conveniently benefit from this system. The simulation work is carried out using MATLAB/SIMULINK.

INTRODUCTION:

Hydrogen energy is recognized as the most promising clean energy source in the 21st century, which possesses the advantages of high energy density, easy storage, and zero carbon emission. Green production and efficient use of hydrogen is one of the important ways to achieve the carbon neutrality. The traditional techniques for hydrogen production such as natural gas reforming, coal gasification, and industrial by-product are accompanied by carbon and polluting gases emission. However, hydrogen production through water electrolysis with the supply of renewable energy has zero carbon emission and environmentally friendly, which is a promising green hydrogen production technology. In particular, proton exchange membrane (PEM) water electrolysis for hydrogen production has the advantages of high current density, high purity of hydrogen production and small footprint. And it is suitable for integrating with the highly volatile renewable energy generation such as solar and wind power generation. Therefore, it is important to develop renewable energy coupled with PEM water electrolysis for hydrogen production. Under the double stress of current environmental pollution and energy crisis, the portion of renewable energy in the power market is increasing by years, among which photovoltaic (PV) power is one of the most popular and large-scale green power generation routes. However, PV power generation has strong volatility and high energy loss due to the influence of natural environmental factors. Therefore, once PV power generation is coupled with water electrolysis for hydrogen production, which converts electric energy into hydrogen energy and then stores and utilizes it, solar energy utilization efficiency can be improved and light discard rate can be reduced. The coupling modes of PV power generation and water electrolysis for hydrogen production is divided into direct and indirect coupling. The direct coupling mode does not require auxiliary equipment such as DC/DC converters and maximum power point tracking (MPPT) devices, and thereby reduces losses in the energy transfer process, but higher requirements lie in the structural matching of the PV array and the electrolyzer. Most studies on direct coupling of PV and water electrolysis have been reported, which mainly involve model optimization analysis aiming at minimizing energy transfer loss or maximizing hydrogen production. For instance, the direct coupling system of PV and water electrolysis was modeled and analyzed with the goal of maximum hydrogen production, and the optimal number of series and parallel PV cells coupled with a single PEM electrolyzer is obtained by optimization analysis, Moreover, the effects of PV cell type and solar irradiance on the hydrogen production efficiency of the direct-coupled system were explored in detail, it was found that the proposed optimized coupling method can effectively improve the hydrogen production efficiency up to 8%. The direct coupled PV-PEM electrolyzer system was modeled and analyzed aiming at minimizing energy transfer loss, but the specific relationship between minimizing energy transfer losses and maximizing hydrogen production was not addressed. The multi-objective optimization of a direct-coupled PV-PEM electrolyzer system was conducted by means of an imperialistic competition algorithm, which considers both minimization of energy transfer losses and maximization of hydrogen production. After a specific case study, the difference between minimization of energy transfer losses and maximization of hydrogen production was found. The optimal system aiming at maximizing hydrogen produces 2.2% more hydrogen than the optimal system aiming at minimizing energy transfer losses, however, the former suffers from more than 68% energy transfer loss. On this basis, a multi-objective optimization technique is proposed, with the objective of minimizing energy transfer losses and maximizing the hydrogen production rate. The proposed model is conductive to analyze the impact of each component on the overall structure and evaluate the system economics. Although the direct coupled systems reduce the cost and complexity of the overall system, considerable energy waste resulted from the mismatch between the PV cell and electrolyzer exists, which results in the necessity for the optimization of system. In addition, the direct coupled system also needs accurate and periodic fine-tuning of system parameters, increasing the instability of the system. Up to now, indirect PV-electrolyzer coupling is still the most common coupling mode. Due to the complexity of indirect coupling system, the high energy transfer loss and cost, better reduction of energy transfer loss and cost are the focus of current research, and many optimization models and energy management strategies have been proposed. A coupled PV-Battery-PEM methanol electrolysis system was proposed, in which methanol was used instead of water, the optimal energy management strategy was investigated at 80 ◦C to improve system efficiency. Simulations were conducted to compare the two installation methods of horizontal and tilted PV arrays, and results showed that the tilted PV array system has better performance. An energy management strategy was proposed for a stand-alone PV coupled electrolytic hydrogen production system, and the feasibility of this energy management strategy was verified by specific experimental cases. In addition to meeting the needs of the user’s electrical load, the remaining energy was used for water electrolysis to produce hydrogen. Another energy management strategy for stand-alone PV hydrogen production systems has been proposed with the aim of reducing the battery size and loss by reducing the energy circulating in the battery, and the strategy has been validated in real operations. The optimal size of the electrolyzer for both configurations with and without battery was investigated, and results show that the size and cost of electrolytic cell can be effectively reduced by adding storage battery. A multifunctional air dehumidification/hydrogen production system driven by PV was developed, and its all-day operational performance under different solar irradiance was experimentally investigated. Results showed that the multifunctional system still had good stability under large fluctuations in solar irradiation throughout the day, but only 1.1% of solar energy in this system was used for electrolysis. A novel hydrogen production approach is proposed using full spectrum solar energy by combining photothermal synergistic reaction with photovoltaic power generation electrolytic water, the simulation results show that the efficiency of the proposed hydrogen production approach reaches 21.05% when the elementary reaction time is 1 ns. In addition, a hybrid hydrogen production method is proposed by combining photothermal cooperative reaction with PV/T power generation electrolytic water, and the highest efficiency of the hybrid hydrogen production reaches 20.52% when the PV cell material is GaAs. It provides a new idea for photovoltaic hydrogen production. The indirect coupling system has better reliability, higher efficiency and higher hydrogen production, but it requires more auxiliary equipment, which leads to the higher investment and maintenance costs. Therefore, further reduction in the cost of the indirect coupling system is a research direction. Most current indirect coupling systems focus on hydrogen production using the remaining energy in the system or energy management strategy with the goal of stabilizing the DC bus voltage only, but few systems focus on the goal of all-day stable hydrogen production, which is important for the future large-scale hydrogen utilization.

PROBLEM STATEMENT :

In this, a PV-Battery-PEM water electrolysis system for hydrogen production was developed with an energy management strategy aiming at maintaining stable DC bus voltage and meeting the all-day stable hydrogen production. The energy efficiency of system with battery for energy storage was evaluated. The proposed system integrates solar PV as the primary energy source, supported by a battery storage unit and a hydrogen generation and storage subsystem, to ensure a reliable and continuous energy supply. The solar PV system harnesses solar energy during daylight hours, while excess energy is used to charge the battery and produce hydrogen through electrolysis. The stored hydrogen serves as a long-term energy reserve, which can be converted back into electricity via a fuel cell when solar generation is insufficient, such as during night time or cloudy periods. The battery system provides short-term energy storage to balance the intermittent nature of solar power and to supply instantaneous power demands. The AI-driven system will strategically allocate surplus electricity generated during peak production phases to power an Proton Exchange Membrane (PEM) electrolyzer. This electrolyzer will efficiently convert excess electricity into hydrogen, storing it for later use in a fuel cell capable of providing electricity during periods of high demand and when solar panels are inactive.

OBJECTIVES :

The objective of this research extends beyond mere prediction and efficiency measurement. It aspires to showcase a comprehensive AI-powered energy management system that not only maximizes the utilization of renewable energy sources but also optimizes hydrogen production for efficient energy storage and subsequent utilization. The ultimate goal is to contribute to sustainable energy solutions by offering a scalable model for the seamless integration of AI into energy management, thereby promoting clean and effective energy usage in our constantly evolving world. Through this work, we aim to pave the way for intelligent and environmentally conscious energy systems that have the potential to make a substantial impact on global energy sustainability and management.

• Demo Video

• Complete project

• Full project report

• Source code

• Complete project support by online

• Life time access

• Execution Guidelines

• Immediate (Download)

Software Requirements:

1. Matlab 2014A and Above

2. simpowersystems toolbox

Hardware Requirements:

1. PC or Laptop

2. 500GB HDD with 1 GB above RAM

3. Keyboard and mouse

1. Immediate Download Online